Understanding EV Charger Type 2: Design, Functionality, and Safety Features

Overview of the IEC 62196 Type 2 Connector and Its Widespread Adoption in Europe

Type 2 connectors under the IEC 62196 standard have become the go-to solution for electric vehicle charging all over Europe, accounting for around 43 percent of public charging stations as of last year. These connectors are built for three phase AC power delivery and can handle up to 22 kilowatts through their seven pin setup which includes three phase wires, a neutral line, grounding connection, plus two extra pins for communication purposes. Back in 2014, when the European Commission mandated that all member countries adopt Type 2 compatibility, this really pushed things forward. What we saw was the creation of what's now essentially one big charging network across the continent where drivers don't have to worry about whether their car will work at any given station.

How the Type 2 Connector Enables Secure, Efficient, and Standardized Power Transfer

Type 2 connectors deliver power reliably thanks to their locking system which keeps them securely connected while charging takes place. The built in data pins let vehicles talk to chargers continuously, so they can adjust how much electricity flows based on what the car actually needs at any given moment, preventing dangerous overloads. Tests done in real conditions have shown these connectors keep about 98 percent efficiency even when it gets really cold or hot outside, from minus 25 degrees Celsius all the way up to 50 degrees. That makes them around 12 to 15 percentage points better than older connector types, which matters a lot for people who want their EVs to charge properly no matter the weather.

Key Safety Mechanisms Built Into the Type 2 Design for User and Vehicle Protection

Type 2 connectors incorporate three core safety features:

- Temperature monitoring: Sensors detect overheating (>85°C) and trigger automatic shutdown

- IP54 ingress protection: Sealed housing resists dust and water, making it suitable for outdoor use

- Pilot signal verification: Charging begins only after confirming proper grounding and circuit integrity

Laboratory tests confirm these mechanisms reduce electrical fault risks by 91% compared to non-standardized alternatives.

Evolution of the Type 2 Connector: Trends in Durability, Ergonomics, and User Safety

Recent updates in the IEC 62196-2:2022 standard require connectors to endure 500,000 mating cycles-150% more than earlier models. Manufacturers now enhance usability with rotating collars for easier handling, UV-resistant materials to prevent cable degradation, and tactile alignment guides that achieve 99.2% first-time connection success in low-light conditions.

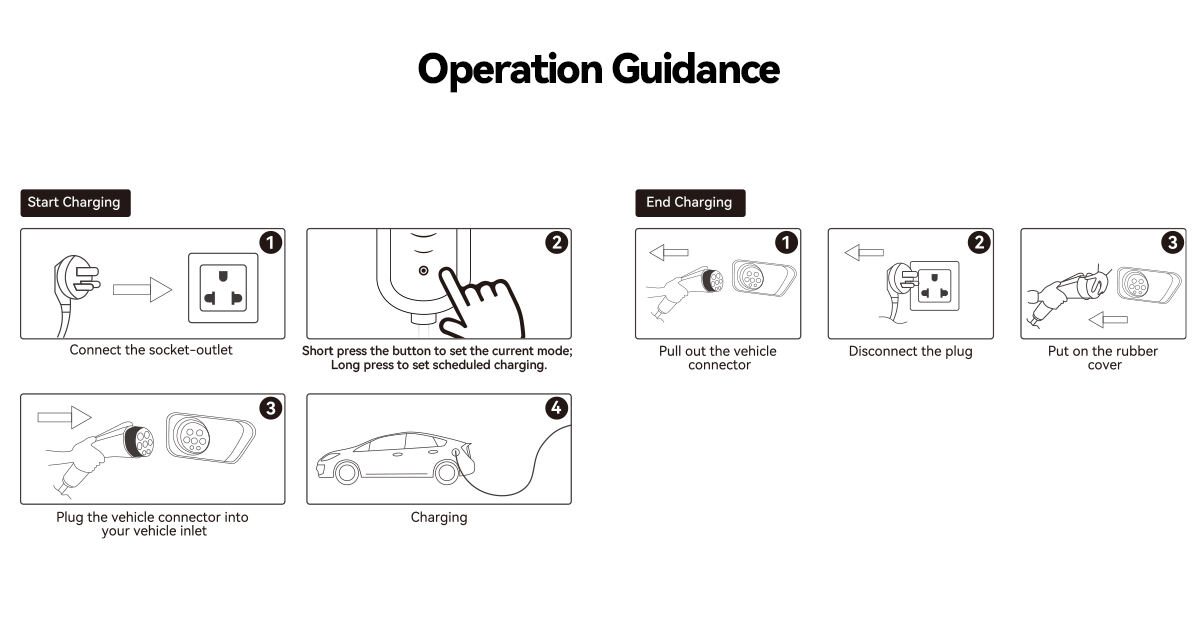

Best Practices for Handling and Connecting the EV Charger Type 2 Safely

Before initiating a charge, users should verify:

1. Connector seals are intact and free of debris

2. Charging port LEDs display steady green status

3. Vehicle dashboard confirms successful communication handshake

A 2023 analysis of 12,000 sessions found that following correct connection procedures reduces wear-related failures by 78%. Certified Type 2 components are designed with <2N resistance to prevent forced insertion, so never apply excessive force when connecting.

Compliance with International Standards: IEC 62196 and IEC 61851 for Safe Charging

Key Requirements of IEC 62196 for EV Charger Type 2 Certification and Interoperability

The IEC 62196 standard sets pretty strict requirements when it comes to Type 2 connector safety and how well they perform. Looking at Part 3 specifically, there are detailed tests for DC charging compatibility. These tests check if connectors can handle voltages going all the way up to 1,000 volts and still work properly in extreme temperatures ranging from minus 25 degrees Celsius right up to 50 degrees. For something to get certified, it needs to withstand around 10,000 times plugging and unplugging without showing any signs of wear or damage according to findings published in the latest 2024 Material Compatibility Report. Getting this kind of certification means different brands' equipment should work together smoothly, which is important because nobody wants problems like electrical sparks or parts warping due to heat buildup during regular use.

Role of IEC 61851 in Defining Grounding, Insulation, and Residual Current Device (RCD) Safety

IEC 61851-23 outlines essential safety measures for AC and DC charging systems:

- Grounding requirements: Limit leakage current to under 30 mA to prevent electric shock

- Insulation monitoring: Automatically cuts power if insulation resistance drops below 50 kΩ

- RCD integration: Detects ground faults within 300 milliseconds to interrupt dangerous circuits

These protocols align with findings from the 2024 Material Compatibility Report, which showed compliant installations reduce electrical faults by 60% compared to non-standard setups.

How Compliance Minimizes Risks of Electrical Faults and System Failures

Following IEC 62196 and IEC 61851 standards basically builds a solid safety system for everyone involved. The standardized PWM signals mentioned in IEC 61851-1 help stop those dangerous overcurrent situations when something gets plugged in. And then there's the part level certification from IEC 62196-2 which keeps connectors working properly even when temperatures get really hot. Looking at what happens in actual commercial operations, companies that stick to these standards tend to spend about 40% less on maintenance work. Plus their equipment lasts significantly longer too, somewhere around seven to ten extra years before needing replacement. That makes sense when we think about how much money gets wasted on premature failures otherwise.

Electrical Safety and Proper Installation of EV Charger Type 2

Ensuring Correct Grounding and Circuit Protection with RCDs for EV Charger Type 2

Getting the grounding right along with those residual current devices (RCDs) matters a lot for making sure Type 2 installations stay safe. Some research from the European Electrotechnical Standards Committee back in 2023 showed pretty impressive numbers too - they claimed RCDs cut down on electrical faults by around 92% specifically for EV charging setups. What these gadgets actually do is shut off power super fast whenever there's more than 30 milliamps leaking through, which stops people from getting shocked. Most pros in the field will go for 40 amp RCDs combined with enclosures rated at least IP54 when putting together systems according to IEC 61851 standards. It's all about following best practices while keeping safety front and center during installation work.

Matching Home Electrical Systems to Type 2 Charger Requirements and Load Capacity

Most homes need electrical upgrades to support Type 2 chargers, which operate between 7.4-22 kW. Essential installation criteria include:

- Dedicated 240V circuits with 32-63A breakers

- Copper wiring (minimum 6mm² cross-section)

- Thermal monitoring for extended charging periods

A 2024 analysis revealed that 68% of charging-related fires stemmed from undersized breakers or aluminum wiring incompatible with sustained high-current loads.

Common Causes of Overheating and Electrical Faults Due to Poor Connections or Substandard Installations

Loose terminal connections account for 41% of Type 2 system failures, according to maintenance reports. Such issues create resistive hotspots reaching 150°C during fast charging-enough to melt insulation. Always follow manufacturer torque specifications (typically 2.5-4 Nm) and avoid uncertified cables lacking built-in temperature sensors.

Avoiding Incompatible or Unauthorized Accessories That Compromise Safety

Non-certified adapters bypass the Type 2 connector’s safety systems, increasing arc flash risk by 300%, per Swiss safety trials. Only use accessories bearing the IEC 62196-2 certification mark, which includes automatic shutoff functionality during abnormal current spikes.

Smart Monitoring Systems: Emerging Trend in Real-Time Anomaly Detection

Modern chargers increasingly feature integrated thermal imaging and predictive analytics that identify issues such as phase imbalance (℉15% variance) 20 times faster than traditional breakers. These systems automatically reduce charging speed when detecting:

- Insulation resistance below 1MΩ

- Ambient temperatures above 45°C

- Voltage fluctuations beyond ±10%

Regular Inspection and Maintenance to Prevent Hazards

Signs of Wear: Cable and Connector Deterioration in High-Use Environments

Type 2 components tend to show signs of wear pretty quickly when they're used often or exposed to harsh environments. The main red flags? Look out for cables that start to fray, insulation cracks forming around them, and contacts that become corroded over time. These issues account for about 78 percent of all problems seen at EV charging points according to the EV Safety Council report from last year. What's interesting is how commercial stations suffer connector damage at roughly triple the rate we see in home setups. Makes sense really since these public chargers get so much more action throughout the day compared to what most people experience at their own garages.

Preventive Maintenance as a Critical Defense Against Fire and Electrical Hazards

Professional inspections every 6-12 months can reduce fire risk by 92% by identifying hidden problems like loose terminals or deteriorated insulation. Thermal imaging is now standard practice for detecting abnormal heat patterns, with fleet operators reporting a 67% drop in downtime after implementing routine scans.

Case Study: Fire Risk Mitigation Through Early Detection of Damaged Type 2 Charging Cables

A 2023 review of 450 public charging stations found that 83% of cable-related fires originated from unrepaired minor damage. One European operator prevented €2.1 million in potential losses by replacing 214 compromised cables identified during dielectric testing-damage invisible to casual inspection but detectable through advanced diagnostics.

Automated Inspection Tools and Diagnostics Adopted by Commercial Fleet Operators

Leading fleets deploy AI-powered diagnostic tools that monitor real-time charging metrics and connector condition. Alerts are triggered by:

- Resistance deviations exceeding ISO 15118 thresholds

- Pin misalignment greater than 0.2mm

- Ground fault currents above 30mA

These systems enable predictive maintenance and significantly reduce unplanned outages.

User Checklist: Inspecting EV Charger Type 2 Equipment Before Each Use

Drivers should check:

- No cracks or discoloration on the connector housing

- Smooth engagement with the vehicle inlet (no excessive force needed)

- No burning smells during initial charging

- Proper cable routing to avoid trip hazards or abrasion

Combining proactive maintenance with user vigilance addresses 34% of charging incidents linked to preventable equipment failures.

Following Manufacturer Guidelines and Mitigating Fire Risks

Why Adhering to Manufacturer Instructions Prevents Misuse and Equipment Damage

Manufacturer guidelines specify voltage tolerances, environmental limits, and approved accessories for Type 2 systems. Deviations-such as using unapproved adapters or exceeding recommended charge cycles-increase insulation degradation risk by up to 40% (IEC, 2022). Following instructions preserves warranty coverage and prevents connector arcing, a leading cause of electrical fires.

Charging in Wet Conditions: Myths vs. Certified Waterproofing Capabilities of Type 2 Connectors

Type 2 connectors have an IP54 rating, protecting against rain and dust, but they are not submersible. While certified for outdoor use, damaged seals can allow moisture ingress, increasing ground fault risk by 27%. Always inspect seals before charging in wet conditions.

Understanding Fire Risks: Insulation Failure, Overheating, and Fast-Charging Stress Factors

Primary fire hazards in Type 2 charging include:

- Thermal runaway from poorly crimped terminals (63% of station fires)

- UV-induced insulation breakdown in aging cables

- Temperature spikes above 50°C at contact points during fast charging

Integrated thermal sensors and adherence to IEC 61851-23 standards are essential for mitigating these risks.

Proven Strategies to Mitigate Fire Hazards in Residential and Commercial EV Charging Setups

Commercial fleets reduced fire incidents by 81% through:

- Biannual torque checks on connector pins

- Infrared inspections of termination points

- Replacing cables after 25,000 charge cycles (industry benchmark)

Residential users should avoid extension cords and opt for hardwired installations with RCD protection.

Are Current Fire Safety Standards Sufficient for High-Power Type 2 Charging Scenarios?

While IEC 62196-2 covers 22 kW AC charging, emerging 44 kW DC applications challenge existing frameworks. A 2023 International Energy Agency report highlighted gaps in standards for liquid-cooled cables and ultra-fast charge cycle management-critical areas needing revision as charging power densities rise by 300% this decade.

FAQs

What is a Type 2 connector?

A Type 2 connector is a charging connector under the IEC 62196 standard, used widely in Europe for electric vehicles. It supports three-phase AC power delivery up to 22 kilowatts.

How do Type 2 connectors enhance safety?

Type 2 connectors include safety features like temperature monitoring, IP54 ingress protection against dust and water, and pilot signal verification to ensure secure and proper charging connections.

Why are IEC standards important for EV chargers?

IEC standards, such as 62196 and 61851, define essential safety and performance requirements for EV chargers, ensuring interoperability, reliability, and reduced risks of electrical faults.

How often should EV charging equipment be inspected?

Professional inspections should be conducted every 6 to 12 months to detect and address potential issues such as loose terminals and insulation wear, thereby preventing fire and electrical hazards.

Table of Contents

-

Understanding EV Charger Type 2: Design, Functionality, and Safety Features

- Overview of the IEC 62196 Type 2 Connector and Its Widespread Adoption in Europe

- How the Type 2 Connector Enables Secure, Efficient, and Standardized Power Transfer

- Key Safety Mechanisms Built Into the Type 2 Design for User and Vehicle Protection

- Evolution of the Type 2 Connector: Trends in Durability, Ergonomics, and User Safety

- Best Practices for Handling and Connecting the EV Charger Type 2 Safely

- Compliance with International Standards: IEC 62196 and IEC 61851 for Safe Charging

-

Electrical Safety and Proper Installation of EV Charger Type 2

- Ensuring Correct Grounding and Circuit Protection with RCDs for EV Charger Type 2

- Matching Home Electrical Systems to Type 2 Charger Requirements and Load Capacity

- Common Causes of Overheating and Electrical Faults Due to Poor Connections or Substandard Installations

- Avoiding Incompatible or Unauthorized Accessories That Compromise Safety

- Smart Monitoring Systems: Emerging Trend in Real-Time Anomaly Detection

-

Regular Inspection and Maintenance to Prevent Hazards

- Signs of Wear: Cable and Connector Deterioration in High-Use Environments

- Preventive Maintenance as a Critical Defense Against Fire and Electrical Hazards

- Case Study: Fire Risk Mitigation Through Early Detection of Damaged Type 2 Charging Cables

- Automated Inspection Tools and Diagnostics Adopted by Commercial Fleet Operators

- User Checklist: Inspecting EV Charger Type 2 Equipment Before Each Use

-

Following Manufacturer Guidelines and Mitigating Fire Risks

- Why Adhering to Manufacturer Instructions Prevents Misuse and Equipment Damage

- Charging in Wet Conditions: Myths vs. Certified Waterproofing Capabilities of Type 2 Connectors

- Understanding Fire Risks: Insulation Failure, Overheating, and Fast-Charging Stress Factors

- Proven Strategies to Mitigate Fire Hazards in Residential and Commercial EV Charging Setups

- Are Current Fire Safety Standards Sufficient for High-Power Type 2 Charging Scenarios?

- FAQs